Table of Contents

- Executive Summary: 2025 Benchmark and Key Findings

- Global Market Forecast: Growth Trajectories & Regional Opportunities (2025–2030)

- Emerging Calibration Technologies: AI, Automation, and Digital Twins

- Key Industry Players & Strategic Partnerships (sources: agilent.com, rohde-schwarz.com, ieee.org)

- Application Spotlight: 5G, Aerospace, and Quantum Computing

- Regulatory Trends & International Standards (source: ieee.org)

- Component Advancements: Materials, Miniaturization, and Chip-Scale Solutions

- Challenges & Solutions: Accuracy, Speed, and Cost Optimization

- Competitive Landscape: M&A, Startups, and New Entrants

- Future Outlook: Disruptive Trends and Strategic Recommendations (2025–2030)

- Sources & References

Executive Summary: 2025 Benchmark and Key Findings

The landscape of microwave circuitry calibration is undergoing notable transformation in 2025, shaped by advances in communications, aerospace, and semiconductor manufacturing. Calibration, which ensures measurement traceability and accuracy for components such as amplifiers, filters, and antennas, is increasingly critical as devices push into higher frequency bands—particularly with the ongoing rollout of 5G and early 6G systems.

In 2025, leading equipment manufacturers and calibration service providers are deploying new automated calibration solutions to address increasing demand for speed, repeatability, and traceability. Keysight Technologies has introduced next-generation vector network analyzer (VNA) calibration kits and automated calibration modules that reduce setup time and operator error. Likewise, Rohde & Schwarz recently expanded its ZNA VNA platform with enhanced calibration routines for millimeter-wave (mmWave) and sub-THz frequencies, targeting both R&D and production-line environments.

Key 2025 benchmarks include:

- Expansion of calibration frequency range: Commercial equipment is now routinely calibrating up to 110 GHz and, in select cases, beyond 130 GHz, supporting research into 6G and automotive radar applications (Anritsu).

- Increased industry adoption of electronic calibration (ECal) modules, which accelerate multi-port calibrations and reduce the need for manual intervention (Keysight Technologies).

- Wider implementation of automated calibration in semiconductor test environments, with Teradyne and Advantest integrating VNA calibration into automated test equipment (ATE) workflows.

- Growth in accredited calibration services, with labs such as National Institute of Standards and Technology (NIST) and Physikalisch-Technische Bundesanstalt (PTB) updating their standards to accommodate higher frequency and tighter uncertainty requirements.

Looking forward, the calibration sector is expected to see stronger collaboration between instrument manufacturers and standards bodies to support the anticipated leap to 6G and terahertz applications. The adoption of AI-driven calibration routines and digital twins for remote verification is being piloted by major players, promising reduced downtime and enhanced predictive maintenance. As industries demand tighter tolerances and faster time-to-market, the role of precise and automated microwave circuitry calibration will only intensify through 2026 and beyond.

Global Market Forecast: Growth Trajectories & Regional Opportunities (2025–2030)

The global market for microwave circuitry calibration is poised for notable expansion between 2025 and 2030, driven by accelerating deployment of advanced wireless technologies, including 5G/6G cellular infrastructure, satellite communications, and emerging quantum and defense applications. As frequency bands used in commercial and governmental systems extend into the millimeter-wave and sub-terahertz ranges, the precision and traceability of calibration processes become mission-critical, underpinning both R&D and production testing workflows.

Market leaders such as Keysight Technologies and Rohde & Schwarz report robust demand for automated vector network analyzer (VNA) calibration kits, calibration services, and software solutions that can address the growing complexity of multi-port, wideband, and on-wafer calibration scenarios. In 2025, Keysight Technologies is rolling out next-generation electronic calibration (ECal) modules designed for frequencies up to 110 GHz, specifically targeting R&D labs and manufacturing lines for advanced radar and mmWave communication systems. Rohde & Schwarz similarly highlights investments in automated calibration routines for over-the-air (OTA) test environments and automotive radar validation, responding to strong growth in both telecom and automotive sectors.

Regionally, North America and Asia-Pacific remain the largest and fastest-growing markets, respectively. In the United States, federal initiatives supporting 5G/6G rollout and aerospace modernization are spurring demand for NIST-traceable calibration standards and services. National Institute of Standards and Technology (NIST) continues to provide calibration artifacts, protocols, and interlaboratory comparisons essential for maintaining global measurement equivalence. In Asia-Pacific, China and South Korea drive significant investment, with companies such as Anritsu and Yokogawa Electric Corporation expanding VNA calibration offerings and local service capabilities to support domestic 5G, satellite, and emerging 6G research initiatives.

Looking ahead, the market outlook from 2025 through 2030 anticipates compounded annual growth in the high single digits, fueled by the proliferation of high-frequency, high-bandwidth applications and increasingly stringent industry standards. Advances in calibration automation, cloud-based data traceability, and remote service delivery are expected to further democratize access to high-precision microwave calibration globally. Collaboration between metrology institutes, industry consortia, and leading instrument manufacturers will be pivotal in establishing new calibration protocols for frequencies above 100 GHz, setting the stage for the next era of wireless innovation.

Emerging Calibration Technologies: AI, Automation, and Digital Twins

Microwave circuitry calibration is undergoing a transformative phase in 2025, driven by the integration of artificial intelligence (AI), automation, and digital twin technologies. These advancements are responding to increasing demands for higher-frequency applications, miniaturized components, and the pervasive rollout of 5G/6G and advanced radar systems. Traditional manual calibration methods are being rapidly supplemented or replaced by innovative, data-driven approaches that enhance accuracy, efficiency, and repeatability.

AI-powered calibration systems are gaining traction due to their ability to process large measurement datasets and dynamically detect anomalies or drift in real time. For example, Keysight Technologies has introduced AI-enhanced calibration routines within its network analyzer platforms, leveraging machine learning algorithms to optimize error correction and reduce human intervention. These AI models can swiftly adapt to variations in environmental conditions, component aging, and system non-linearities, offering a significant leap over static, rule-based calibration tables.

Automation continues to be a focal point, with leading suppliers such as Rohde & Schwarz and Anritsu providing automated calibration kits and software suites for microwave test equipment. These platforms enable closed-loop calibration processes where robotic arms or modular switch matrices configure and measure devices under test with minimal operator input. In 2025, such systems are increasingly being integrated with cloud-based asset management and remote diagnostics, allowing for predictive maintenance and centralized calibration data analytics. This trend is expected to proliferate as industries seek to reduce downtime and ensure traceability across distributed manufacturing sites.

Digital twin technology is emerging as a game-changer in the calibration of complex microwave circuits. By creating virtual replicas of physical test setups and devices, companies can simulate calibration scenarios, analyze system behaviors, and preemptively identify potential sources of error. NI (National Instruments) has actively promoted digital twins in test engineering workflows, where simulated calibration routines can be validated before deployment on physical hardware, thus accelerating development cycles and reducing costly rework. Such approaches also support the calibration of non-standard or custom microwave assemblies, where empirical modeling may be the only viable option.

Looking ahead to the next few years, the convergence of AI, automation, and digital twins is expected to set new benchmarks in microwave calibration precision and scalability. Industry stakeholders are focusing on interoperability, cyber-secure remote access, and compliance with evolving international standards, ensuring that these emerging technologies can be seamlessly adopted across sectors such as aerospace, telecommunications, and automotive radar. As these tools mature, they will likely become integral to next-generation microwave system design and maintenance workflows.

Key Industry Players & Strategic Partnerships (sources: agilent.com, rohde-schwarz.com, ieee.org)

The microwave circuitry calibration sector continues to be shaped by the technological leadership and strategic collaborations of several key industry players. As of 2025, companies like Keysight Technologies (formerly Agilent Technologies), Rohde & Schwarz, and organizations such as the IEEE are at the forefront, driving innovation and standardization in calibration methods for increasingly complex RF and microwave systems.

Keysight Technologies remains an industry leader in microwave calibration, with recent initiatives focusing on modular, automated calibration systems to address the growing demand for high-frequency, high-precision measurements in 5G, satellite, and quantum computing applications. In 2024 and early 2025, Keysight expanded its PathWave Calibration Management software, optimizing workflow integration for large-scale test environments and supporting automated calibration for devices up to 110 GHz. Their ongoing partnerships with leading telecommunications firms and semiconductor manufacturers are accelerating the adoption of new calibration protocols tailored for ultra-wideband and mmWave devices (Keysight Technologies).

Rohde & Schwarz is emphasizing strategic alliances across sectors, particularly with aerospace and defense, where calibration demands are stringent due to the push for higher frequency radar and secure communications. In 2025, Rohde & Schwarz announced joint development programs with global aerospace OEMs, focusing on remote calibration and verification services via cloud-based platforms. Their R&S®ZNA and R&S®ZNB vector network analyzers have set new standards for traceable, automated calibration, supporting frequencies exceeding 67 GHz, with ongoing research into extending this range (Rohde & Schwarz).

The IEEE Microwave Theory and Techniques Society (MTT-S) is playing a pivotal role in defining calibration standards and fostering collaboration between industry and academia. Through 2024 and into 2025, the IEEE MTT-S has hosted international working groups to update calibration protocols for multi-port and nonlinear device characterization, ensuring interoperability among equipment from different manufacturers. Their focus on metrology and traceability is helping unify calibration approaches as new frequency bands and device architectures emerge (IEEE).

Looking ahead, the next few years will see continued integration of AI-driven calibration routines, remote/cloud-based management, and multi-party alliances aimed at reducing downtime and increasing calibration certainty. These strategic developments, led by industry giants and standards bodies, will be fundamental as the industry adapts to the surging complexity and frequency demands of next-generation microwave circuitry.

Application Spotlight: 5G, Aerospace, and Quantum Computing

Microwave circuitry calibration is a foundational process underpinning the performance and reliability of advanced technologies in 5G communications, aerospace systems, and quantum computing. As of 2025, rapid advancements in these sectors are driving demand for more precise, automated, and adaptive calibration solutions.

In 5G infrastructure, operators are deploying millimeter-wave (mmWave) small cells and massive MIMO antennas, which demand routine, high-precision calibration to ensure optimal beamforming and signal integrity. Automated calibration platforms, such as those provided by Keysight Technologies, are increasingly integrated into network maintenance workflows, enabling real-time error correction and reducing downtime. These solutions leverage vector network analyzers (VNAs) and sophisticated software to streamline the calibration process, making it scalable for dense urban deployments.

Aerospace and defense applications, including radar, electronic warfare, and satellite communications, require strict adherence to calibration standards to guarantee mission-critical performance. Organizations like Rohde & Schwarz offer portable and field-deployable calibration instruments that maintain traceability to international standards. In 2024, the U.S. National Institute of Standards and Technology (NIST) introduced new calibration reference artifacts for microwave power and attenuation, further improving measurement reliability for aerospace OEMs and maintenance crews (NIST).

Quantum computing presents unique calibration challenges, as superconducting qubits and control electronics operate at microwave frequencies with unprecedented sensitivity to environmental fluctuations. Companies like Tektronix and NI (National Instruments) are collaborating with quantum labs to develop custom calibration routines that account for cryogenic environments and femtowatt-level signal paths. These efforts focus on minimizing systematic errors and drift in qubit control and measurement channels, which is critical for scaling quantum processors.

Looking ahead, the next few years will see increased adoption of AI-driven calibration tools capable of predictive maintenance and self-optimization. Major players are investing in cloud-connected platforms to aggregate calibration data, enabling remote diagnostics and continuous improvement of test protocols. Open-source initiatives, spearheaded by organizations such as VXI Technology, aim to standardize calibration procedures across the industry, promoting interoperability and lowering barriers for emerging applications.

In summary, microwave circuitry calibration is transitioning from a periodic, manual task to a highly automated, data-driven discipline. This evolution is essential for supporting the expanding capabilities and complexity of 5G, aerospace, and quantum computing systems in 2025 and beyond.

Regulatory Trends & International Standards (source: ieee.org)

The landscape of microwave circuitry calibration is rapidly evolving in 2025, shaped by heightened regulatory scrutiny and the harmonization of international standards. As microwave frequencies are increasingly leveraged for advanced communications, radar, and aerospace applications, calibration protocols are under continuous refinement to ensure accuracy, interoperability, and safety.

A pivotal event in recent years has been the revision and expansion of the IEEE Standard 287, which specifies precision coaxial connectors for RF and microwave measurements. The latest updates, coordinated by the IEEE Standards Association, emphasize more stringent connector repeatability and traceability requirements, impacting both manufacturers and calibration laboratories worldwide. These standards are now being reflected in national metrology bodies’ practices, such as those of the National Institute of Standards and Technology (NIST), which has expanded its calibration service offerings for higher frequency ranges and lower measurement uncertainties.

Internationally, the International Organization for Standardization (ISO) continues to oversee harmonization efforts, with ISO/IEC 17025 remaining the cornerstone for laboratory competence in calibration. In 2025, a new supplement specific to microwave calibration instruments and procedures is under review, aiming to clarify uncertainty budgets and proficiency testing requirements for frequencies above 50 GHz. This supplement is expected to be adopted widely over the next few years, further aligning global calibration practices.

The Physikalisch-Technische Bundesanstalt (PTB) and National Physical Laboratory (NPL) in Europe have also reported significant efforts in inter-laboratory comparisons, focusing on vector network analyzer (VNA) calibration standards and methodologies. These comparisons are designed to validate calibration traceability across borders and support the mutual recognition arrangements (MRAs) that underpin the global trade of microwave components and systems.

Looking forward, regulatory emphasis is shifting towards automated calibration and digital workflow integration, as encouraged by the IEEE and sectoral committees. This is driving the adoption of digital calibration certificates and blockchain-based traceability for critical components. Industry participants, including leading instrument manufacturers such as Keysight Technologies and Rohde & Schwarz, are actively collaborating with standards bodies to ensure their calibration solutions are compliant with emerging regulatory frameworks.

In summary, 2025 marks a period of tightening regulatory frameworks and rapid standardization in microwave circuitry calibration. The outlook for the next few years is clear: greater global harmonization, higher calibration precision requirements, and the digitization of compliance processes—all of which are set to redefine best practices in the field.

Component Advancements: Materials, Miniaturization, and Chip-Scale Solutions

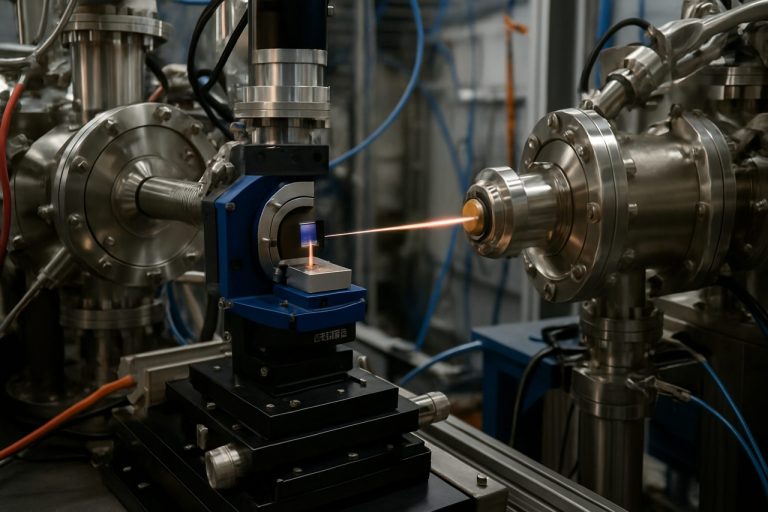

The ongoing evolution of microwave circuitry calibration is being driven by rapid advancements in component materials, the push towards miniaturization, and the proliferation of chip-scale solutions. As systems in sectors such as telecommunications, aerospace, and automotive radar demand higher frequencies, better linearity, and lower insertion losses, precise calibration becomes imperative to ensure optimal system performance.

In 2025, leading component manufacturers are introducing novel materials—such as advanced ceramics and low-loss laminates—to mitigate signal degradation and improve repeatability in calibration routines. For instance, Rohde & Schwarz and Keysight Technologies have both released new calibration kits and precision adapters using improved substrate materials that minimize parasitic effects at millimeter-wave frequencies. These materials support the tight tolerances required in chip-scale and miniaturized systems, where even minor impedance mismatches can lead to significant measurement errors.

Miniaturization is another dominant trend, with calibration standards and verification tools now being offered in ultra-compact formats. Anritsu has recently developed modular, pocket-sized vector network analyzer (VNA) calibration kits, enabling field engineers to perform on-site calibration with the same accuracy as in laboratory environments. Concurrently, National Instruments is advancing integrated calibration routines for software-defined radio (SDR) platforms, leveraging the programmability of chip-scale systems to allow real-time, automated self-calibration.

Chip-scale solutions are also transforming the calibration landscape. The integration of calibration references, such as on-chip standards and tunable elements, is reducing reliance on bulky external equipment. For example, Qorvo is incorporating on-chip calibration structures into its RF front-end modules, allowing dynamic compensation for process variations and environmental changes. This shift is expected to accelerate through 2025 and beyond, as the industry moves toward highly integrated, software-managed calibration frameworks.

Looking ahead, industry bodies like the IEEE are working to standardize calibration procedures for emerging materials and chip-scale architectures, ensuring interoperability and measurement traceability as frequency ranges extend into the sub-terahertz domain. The convergence of advanced materials, miniaturization, and chip-scale integration signals a future where precise, automated, and universally compatible microwave calibration is both achievable and necessary to support next-generation applications.

Challenges & Solutions: Accuracy, Speed, and Cost Optimization

Microwave circuitry calibration is a cornerstone for high-frequency electronics, especially as the industry pushes toward 5G, 6G, and advanced radar applications in 2025 and beyond. The sector faces three persistent challenges: maintaining accuracy at ever-higher frequencies, increasing calibration speed to meet production demands, and optimizing costs amid rising complexity.

Accuracy is challenged by the proliferation of millimeter-wave (mmWave) and sub-THz devices. As frequencies rise above 40 GHz, even minor connector or cable inconsistencies can introduce significant errors. Leading instrument manufacturers such as Keysight Technologies and Rohde & Schwarz have responded by releasing vector network analyzers (VNAs) with enhanced directivity and dynamic range, and by supporting advanced calibration methods like Automatic Fixture Removal (AFR) and electronic calibration (ECal). These solutions minimize operator error and environmental sensitivity, but require precise, traceable standards and regular validation, adding to operational complexity.

Speed is now a critical differentiator as production lines for modules, antennas, and systems scale up for telecom and automotive radar. Companies like Anritsu have introduced multiport VNAs and software automation suites that dramatically reduce test and calibration cycle times. Automated calibration units (ACUs) and remote test management are increasingly standard. However, balancing speed with accuracy remains difficult: rapid switching and high-throughput scenarios can compromise measurement integrity unless calibration routines are meticulously maintained and equipment is regularly serviced.

Cost optimization is increasingly important as the cost of test can represent a substantial portion of total product cost, particularly in consumer electronics and automotive sectors. To address this, industry leaders such as NI (National Instruments) have focused on modular instrumentation, allowing reuse of core VNA platforms with application-specific frontends, and on software upgrades that extend instrument life cycles. There is a trend toward shared calibration labs and cloud-based calibration management, reducing the need for expensive, dedicated in-house equipment. Nevertheless, the need for periodic recalibration, traceability, and certification—especially in safety-critical applications—limits how far costs can be reduced without impacting quality.

Looking ahead into 2026 and beyond, industry bodies such as the IEEE are working on standardizing calibration procedures for emerging frequency bands and device types. Solutions leveraging machine learning for real-time calibration correction and self-diagnosing instruments are under active development, promising to improve all three axes: accuracy, speed, and cost. However, widespread adoption will depend on demonstrated reliability and interoperability with legacy systems.

Competitive Landscape: M&A, Startups, and New Entrants

The competitive landscape of microwave circuitry calibration in 2025 is marked by significant consolidation, increased startup activity, and the emergence of new entrants leveraging AI and digitalization. Established players such as Keysight Technologies, Rohde & Schwarz, and Anritsu Corporation are actively expanding their calibration services and solutions portfolios through both strategic acquisitions and in-house innovation.

In the last year, Keysight Technologies announced the expansion of its PathWave Test software suite, integrating enhanced automation features for microwave calibration workflows. This positions Keysight to tap into the growing demand for automated and remote calibration in 5G, radar, and satellite applications. Similarly, Rohde & Schwarz has broadened its calibration service network, opening new centers in North America and Asia to address the regional demand for high-precision RF and microwave calibration, especially in the telecommunications and aerospace sectors.

On the M&A front, 2024 saw TestEquity acquire several regional calibration service providers, including Continental Resources, strengthening its position in the North American calibration market. This consolidation trend is expected to continue into 2025, as global supply chains and equipment manufacturers seek reliable, full-spectrum calibration partners.

Startups are also shaping the competitive landscape. Companies like Proteq Solutions and Quantifi (focused on AI-driven calibration analytics and digital twin technologies) are gaining traction for their cloud-connected calibration platforms. These solutions offer predictive maintenance and real-time performance monitoring, targeting both R&D and production environments.

New entrants are leveraging disruptive technologies, such as machine learning for calibration optimization and blockchain for traceability in calibration certificates. Industry bodies like the National Conference of Standards Laboratories International (NCSLI) are also revising guidelines to accommodate these digital innovations, fostering a more open and standardized calibration ecosystem.

Looking ahead, the competitive landscape in microwave circuitry calibration is expected to favor companies with digital capabilities, global reach, and strong industry partnerships. The convergence of traditional metrology expertise and digital transformation will drive further M&A, while startups and new entrants continue to inject agility and innovation into the sector.

Future Outlook: Disruptive Trends and Strategic Recommendations (2025–2030)

The period from 2025 through 2030 is poised to be transformative for microwave circuitry calibration, driven by a convergence of technological advancements, automation, and evolving application demands. As the rollout of 5G and the initial development of 6G networks progress, the calibration of microwave circuits—especially in the mmWave and sub-THz bands—becomes increasingly critical for ensuring reliability and performance in telecommunications, aerospace, and defense systems. Key disruptive trends are emerging in both the instrumentation and methodologies used for calibration.

- Automation and AI-driven Calibration: Instrument manufacturers are integrating AI and advanced software into vector network analyzers (VNAs) and calibration kits, enabling real-time error correction and automated calibration procedures. For example, Keysight Technologies and Rohde & Schwarz are deploying machine learning algorithms to predict drift, optimize measurement routines, and even flag faulty setups. These advances reduce human error and speed up calibration cycles, which is essential for high-volume production and field deployment.

- Remote and Cloud-based Calibration Services: The shift toward remote operations is accelerating the adoption of cloud-connected calibration platforms. Anritsu and Copper Mountain Technologies are expanding solutions where calibration data and system diagnostics can be accessed, managed, and even performed remotely, leveraging secure cloud services for traceability and compliance.

- Higher Frequency and Multi-port Calibration: The push into higher frequencies (up to 330 GHz and beyond) and the proliferation of multi-port devices are challenging traditional calibration techniques. Manufacturers such as HUBER+SUHNER are innovating on precision calibration standards and connectors to minimize uncertainties in these higher-frequency regimes. Modular and scalable calibration units are being introduced to support multi-port device testing, which is essential for massive MIMO and phased-array antenna systems.

- Traceability and Standardization: Industry organizations, including National Institute of Standards and Technology (NIST), are working with stakeholders to define new calibration standards and traceability protocols for emerging frequency bands. This will be crucial for global interoperability and quality assurance in next-generation wireless and satellite communications.

Strategic Recommendations: To remain competitive, organizations should invest in automation-ready, remotely upgradeable calibration systems, prioritize partnerships with vendors offering cloud-based calibration management, and actively participate in industry standardization initiatives. As the calibration landscape evolves, aligning early with these disruptive trends will be key to unlocking performance gains and operational efficiencies in microwave circuit design and deployment.

Sources & References

- Rohde & Schwarz

- Advantest

- National Institute of Standards and Technology (NIST)

- Physikalisch-Technische Bundesanstalt (PTB)

- Yokogawa Electric Corporation

- NI (National Instruments)

- IEEE

- IEEE

- Tektronix

- VXI Technology

- International Organization for Standardization (ISO)

- National Physical Laboratory (NPL)

- TestEquity

- Proteq Solutions

- Copper Mountain Technologies

- HUBER+SUHNER